Is Circular Saw Blade Steel Good For Knife Making? There are a lot of different materials that can be used for knife making, and one of them is circular saw blade steel. This type of steel is often used for making knives because it is very strong and durable. It is also relatively easy to find and relatively inexpensive.

However, there are a few things that you should know before using this type of steel for your next knife project.

Making a knife with a circular saw

There’s a lot of debate among knife makers about what kind of steel is best for knife making. Some say that circular saw blade steel is the best because it’s tough and holds an edge well. Others say that it’s too difficult to work with and not worth the effort.

Personally, I think that circular saw blade steel can be great for knife making if you know what you’re doing. It’s definitely tougher than most other steels, so it can take a beating without breaking. And if you heat treat it correctly, it will hold an edge really well.

However, working with this kind of steel is definitely more challenging than some others. It’s important to have good tools and be very careful when cutting or grinding it. Otherwise, you’ll end up with a lot of broken blades!

Credit: feltmagnet.com

Can I Use Circular Saw Blade to Make a Knife?

If you’re looking to make a knife out of a circular saw blade, the short answer is yes. However, it’s important to note that this isn’t going to be an easy process and there are some things you’ll need to keep in mind.

First, it’s important to choose the right blade.

A standard wood-cutting blade is not going to be ideal for this project. Instead, you’ll want to look for a steel-cutting or metal-cutting blade. These blades are designed to cut through tougher materials and will be much better suited for the task at hand.

Next, you’ll need to take care in cutting the blade. When cutting the steel, it’s important to use a slower speed and apply more pressure than you would when cutting wood. This will help ensure that the blade doesn’t overheat and become damaged during the process.

Finally, once you’ve cut the blade into shape, you’ll need to sand and polish it until it’s smooth and sharp enough to use as a knife. This is definitely not a project for beginners but with patience and attention to detail, it can definitely be done!

What Type of Steel is a Circular Saw Blade Made Of?

Circular saw blades are made of a variety of different steels. The most common type of steel is high-speed steel, which is a very hard and durable alloy. Other types of steel that are used include tool steel, stainless steel, and tungsten carbide.

What Kind of Steel Should I Use to Make a Knife?

There are a few things to consider when choosing the type of steel to use for a knife. The first is the hardness of the steel. Harder steel will hold an edge better but is more difficult to sharpen. Softer steels are easier to sharpen but won’t hold an edge as well. The second thing to consider is the level of carbon in steel. A higher carbon content will make the steel harder but also more brittle.

For a knife, you’ll want to choose a balance between hardness and toughness so that it can withstand regular use without breaking. Some common types of steel used for knives are 1095, 5160, and O1. 1095 is a high-carbon tool steel that offers good wear resistance at a relatively low price point.

Use still to make a knife

It’s often used for budget knives as it’s easy to heat treat and shape into blades. However, because it’s not as tough as some other steels, it’s not ideal for heavy-duty use or hard-use knives that might see abuse on a regular basis. 5160 is another popular option, especially for larger knives like bushcraft or survival knives.

It has good toughness and edge retention while still being relatively easy to work with during the forging process. One downside to 5160 is that it can be prone to rust if not properly cared for so it’s important to keep your knife clean and dry if you opt for this type of steel. O1 is a versatile tool steel that offers good wear resistance and toughness at a reasonable price point.

It’s often used in woodworking tools like chisels due to its ability to resist impact damage without breaking or shattering.

What is the Best Metal to Make a Knife Blade Out Of?

The answer to this question is not as simple as it may seem. There are a variety of factors that must be considered when deciding which metal to use for a knife blade. These factors include the hardness of the metal, the ability of the metal to take and hold an edge, and the overall durability of the metal.

With that said, there are a few metals that are commonly used for knife blades and each has its own advantages and disadvantages. Some of the most common metals used for knife blades are stainless steel, carbon steel, and tool steel.

Stainless Steel

Stainless steel is perhaps the most popular choice for knife blades because it is highly resistant to corrosion and staining.

Carbon Steel

Carbon steel is another popular choice because it is very hard and can take and hold a sharp edge very well. However, carbon steel is also more susceptible to rusting than stainless steel. Tool steel is often used for high-end knives because it is extremely hard and durable.

However, tool steel can be difficult to work with and can be quite expensive. In general, stainless steel or carbon steel are good choices for knife blades. Both materials are relatively easy to work with and will provide a durable, long-lasting blade.

Can You Harden a Saw Blade?

What Steel are Saw Blades Made from

Saw blades are one of the most important tools in a woodworker’s arsenal. They come in all shapes and sizes, but they all have one thing in common: they’re made from steel.

There are a few different types of steel that saw blades can be made from, each with its own advantages and disadvantages.

The type of steel that a blade is made from will affect its price, durability, and cutting performance.

The most common type of steel used for saw blades is carbon steel. Carbon steel is strong and durable, but it can be susceptible to rusting if not properly cared for.

It’s also relatively affordable, making it a good choice for budget-conscious woodworkers.

High-speed steel (HSS) is another popular option for saw blades. HSS holds an edge better than carbon steel and is less likely to chip or break under heavy use.

However, it costs more than carbon steel and can be difficult to work with if you’re not experienced.

Cobalt alloy steels are also available, but they’re primarily used for industrial applications due to their high cost. These steels hold an edge exceptionally well and resist wear better than any other type of blade material, but they require special care to avoid damage.

Circular Saw Blade Material

There are many different types of circular saw blades available on the market, each designed for specific materials. The most common materials used for circular saw blades are steel, tungsten carbide, and diamond. Steel is the most economical option and works well with a variety of materials, including wood, plastic, and metal.

Tungsten carbide is a more expensive option but it is much harder than steel and can withstand higher temperatures. Diamond is the most expensive option but it is also the hardest material and can cut through almost anything. When choosing a circular saw blade, be sure to select one that is designed for the material you will be cutting.

Using the wrong blade can damage your saw or cause injury.

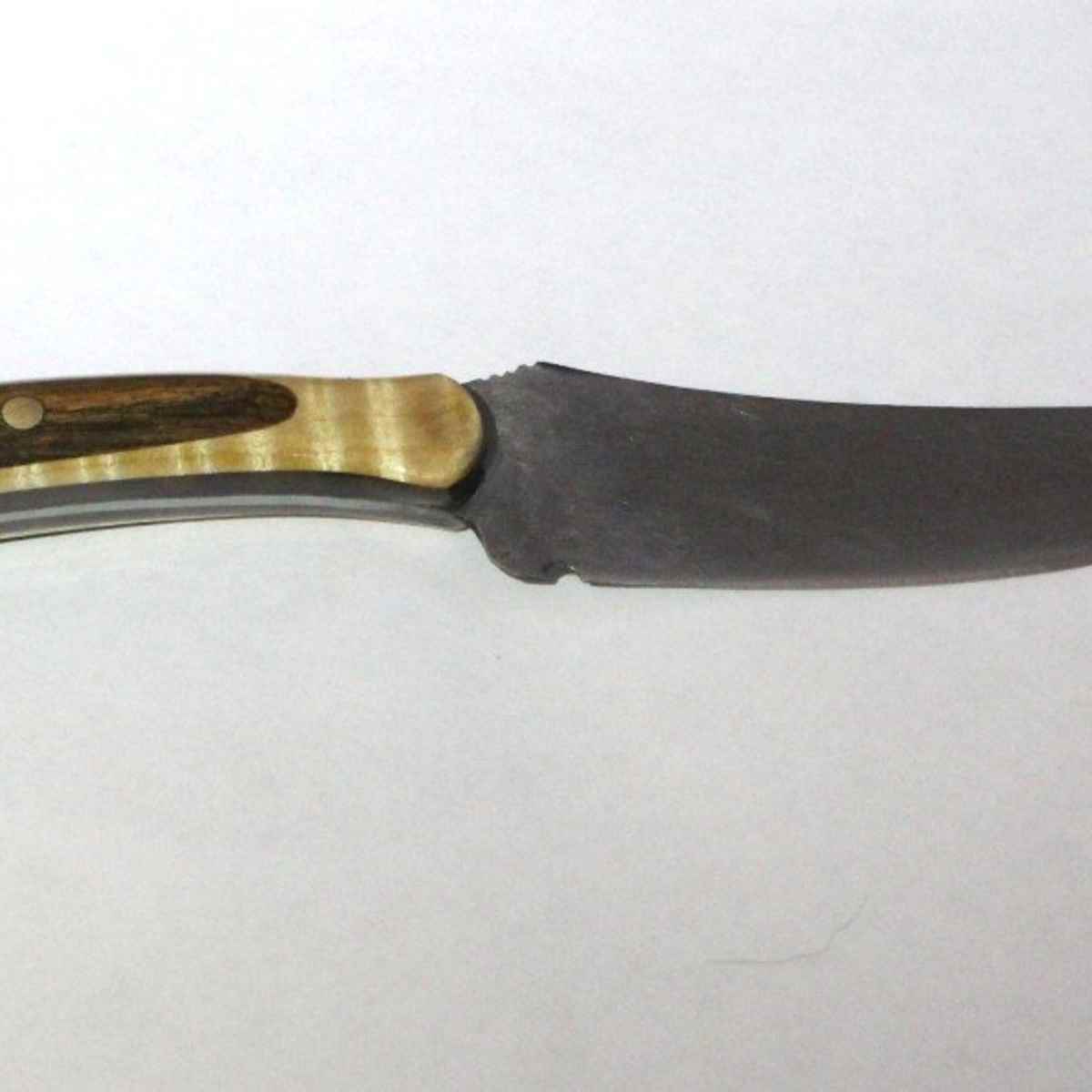

Knives Made from Hand Saw Blades

As anyone who’s done any woodworking knows, a handsaw is only as good as its blade. And when it comes to blades, there are few that can match the durability and cutting power of a hand saw blade. That’s why many knife makers have started using them to create high-quality knives.

The most popular type of knife made from a hand saw blade is called a “bowie knife.” Named after famous American frontiersman Jim Bowie, these knives are known for their large size and impressive strength. But they’re not just used for hunting – many people find them useful for survival situations as well.

Another type of knife that’s often made from a hand saw blade is called a “kukri.” This type of knife originated in Nepal, and it has a curved blade that makes it perfect for chopping vegetables or meat. It can also be used as a tool for self-defense.

Saw Blades for Knife Making

If you’re a knife maker, then you know that having the right saw blade is essential to getting a clean cut. But with so many different types and sizes of saw blades available, it can be tricky to know which one is best for your project. In this article, we’ll take a look at some of the most popular saw blades used for knife making, so you can choose the best one for your needs.

The first thing to consider when choosing a saw blade is the type of steel. For most knife projects, high-carbon steel is the best choice. It’s strong and durable and holds an edge well.

However, it can be difficult to work with if you’re not experienced in using power tools. If you’re just starting out, or if you don’t have access to a lot of power tools, then stainless steel may be a better option. It’s easier to work with, but it doesn’t hold an edge as well as high carbon steel.

Size of Blade

Once you’ve decided on the type of steel you want to use, the next thing to consider is the size of the blade. Saw blades come in all sorts of different sizes, from small hand-held blades to large stationary ones. The size you need will depend on the project you’re working on.

If you’re just cutting some basic shapes out of wood or plastic, then a small hand-held blade will do just fine. But if you’re cutting through thick pieces of metal or hardwood, then you’ll need something much larger. Finally, think about how many teeth per inch (TPI) you need on your blade.

The higher the TPI, the finer the cut will be. If you’re doing precision work or working with delicate materials like glass or stone, then a higher TPI is necessary so that your cuts are clean and precise.

Conclusion

Circular saw blades are not typically made of steel good for knife making. The steel is too hard, which makes it difficult to sharpen and can cause the blade to break.

If you’re looking for a durable and powerful knife, then one that’s been made from a hand saw blade is definitely worth considering. Just make sure you get one from a reputable manufacturer so you know it will be up to the task at hand!

I’m John Carry, also known as a woodworker I have been a professional saw expert for over 10 years. I’d work with every type of saw machine out there, and experiment to find which tools work better.

I’m always looking for ways to improve my skills and help those around me. I love my job and am always happy to share my knowledge with others.