Can a Reciprocating Saw Cut Curves? A reciprocating saw is a versatile tool that can be used for a variety of tasks, including cutting curves. While it’s not the ideal tool for every curve-cutting job, it can handle many types of curves with ease. Here’s a look at how to use a reciprocating saw to cut curves, as well as some tips on getting the best results.

Curves cut with a Reciprocating Saw

A reciprocating saw is a versatile tool that can be used for a variety of tasks, including cutting curves. While it may not be the ideal tool for every curve-cutting job, it can handle many types of curves with ease. When choosing a reciprocating saw for curve-cutting, it’s important to consider the size and type of blade you’ll need, as well as the power of the saw.

With the right tools and techniques, you can cut any type of curve with a reciprocating saw.

Credit: www.woodworkingtalk.com

Which Saw is Suitable for Curve Cutting?

Assuming you are talking about hand saws, the best type of saw for curve cutting is a Japanese pull saw. These saws have very thin blades that can make tight turns and curves. The blade is also removable so you can easily change it out if it gets dull.

How Do You Cut Curved Shapes in Wood?

To cut a curved shape in wood, you will need to use a jigsaw. First, mark out the shape that you want to cut on the piece of wood. Then, using a sharp blade, carefully cut along the line that you have marked out.

Be sure to keep your hands well away from the blade as you are cutting. If you want to create a more precise curve, then you can use a router. First, mark out the shape that you want to cut on the piece of wood.

Then, using a router bit that is slightly smaller than the width of your desired curve, route along the line that you have marked out. Again, be sure to keep your hands well away from the router bit as you are working.

What Will a Reciprocating Saw Cut?

A reciprocating saw is a versatile tool that can be used for a variety of tasks, including cutting through wood, metal, and plastic. It is a handheld power tool that features a blade that moves back and forth in a rapid motion, allowing the user to make quick and precise cuts. One of the most common uses for a reciprocating saw is cutting through lumber.

The blade on the saw can easily cut through 2x4s and other types of wood. When cutting lumber with a reciprocating saw, it is important to use the proper blade type to avoid damaging the material. For example, if you are cutting pressure-treated lumber, you should use a carbide-tipped blade as these are designed to resist corrosion from chemicals found in the wood.

In addition to cutting wood, reciprocating saws can also be used to cut through metal and plastic materials. The blades on these saws are designed to cut through tougher materials, such as rebar or PVC piping. When cutting through metal or plastic, it is important to use caution as these materials can cause the blade to bind or overheat if not used properly.

Overall, reciprocating saws are versatile tools that can be used for a variety of tasks. With the right blade type installed, they can easily cut through wood, metal, and plastic materials quickly and efficiently.

What 2 Cuts Can Be Made With a Reciprocating Saw?

A reciprocating saw is a versatile tool that can be used for a variety of tasks. The two main cuts that can be made with a reciprocating saw are straight cuts and curved cuts. Straight cuts are the most common type of cut made with a reciprocating saw.

To make a straight cut, simply line up the blade of the saw with the desired cutting line and slowly guide the tool along the line. Be sure to keep your hand steady and apply gentle pressure to avoid veering off course. Curved cuts are slightly more difficult to execute but can be very useful in certain situations.

To make a curved cut, first mark out the area you wish to cut with a pencil or pen. Then, use the tip of the blade to start cutting at one end of the curve and slowly follow it around until you reach the other end. Again, take care to keep your hand steady and apply gentle pressure throughout the process.

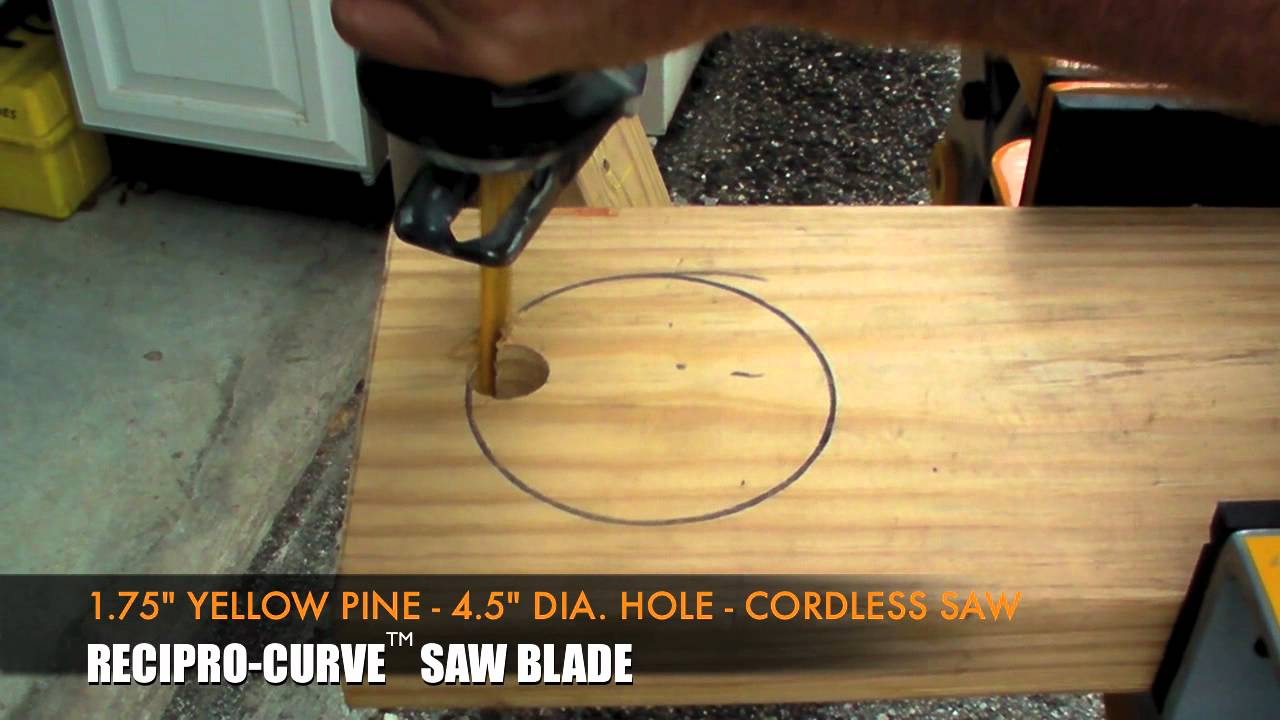

RECIPRO-CURVE SAW BLADES

Cutting Curves in Thick Wood

One of the most difficult woodworking tasks is cutting curves in a thick wood. This is because the thickness of the wood makes it difficult to maneuver the saw blade around tight corners. As a result, many people end up with jagged and uneven cuts.

If you’re faced with this task, there are a few things you can do to ensure a successful cut. First, use a sharp saw blade. A dull blade will make it even more difficult to get clean cuts.

Second, take your time and go slowly. It’s better to make several small cuts than one big one. And finally, be careful not to force the saw blade through the wood – let it do the work for you.

With these tips in mind, cutting curves in thick wood doesn’t have to be so daunting. Just take your time, use a sharp blade, and be careful not to force the saw and you’ll be sure to get clean cuts every time.

How to Cut Straight With a Reciprocating Saw

If you’re looking for a powerful tool that can help you tackle a variety of projects, look no further than a reciprocating saw. Also known as a Sawzall, this tool is ideal for cutting through materials like wood, metal, and plastic. The key to making clean, straight cuts with a reciprocating saw is to use the right blade for the job and to take your time.

With these tips in mind, you’ll be able to make professional-looking cuts in no time! The first step is to select the right blade for the job at hand. If you’re cutting through wood, opt for a blade with fewer teeth per inch (TPI).

This will help prevent the blade from getting stuck in the material. For tougher jobs like metal or concrete, choose a blade with more TPI. Once you’ve selected the appropriate blade, it’s time to get started!

To make straight cuts, start by clamping your workpiece down securely. Then, line up the edge of the blade with your desired cut line. Be sure to hold the saw firmly with both hands as you begin cutting.

When it comes to actually make the cut, go slowly and steadily – there’s no need to rush! As you near the end of your cutline, slow down even more so that you don’t overshoot your mark. With these tips in mind, cutting straight lines with a reciprocating saw will be a breeze!

Types of Curve Cutting Saws

A curve-cutting saw is a powerful tool that is used to cut curves in wood. There are two main types of curve-cutting saws: jigsaws and band saws. Jigsaws are the most common type of curve-cutting saw.

They are small, handheld power tools that can be fitted with a variety of blades to enable them to cut different shapes. Jigsaws are very versatile and can be used to create both simple and complex curves. Band saws are larger, more powerful machines that are capable of cutting much thicker pieces of wood than jigsaws.

Band saws have a blade that runs around a continuous loop, making them ideal for cutting long, straight lines or large circles. However, band saws can be more difficult to control than jigsaws and so they are not always the best choice for intricate curves.

How to Cut Curves in Wood Without a Bandsaw

If you’re working with wood, there’s a good chance that you’ll need to cut curves at some point. Curves can add interest and variety to your projects, but they can be tricky to cut without the right tools.

Bandsaws are specifically designed for cutting curves, so they’re the ideal tool for the job.

However, if you don’t have a bandsaw (or if you just want to try something different), there are other ways to cut curves in wood.

One option is to use a jigsaw. Jigsaws are versatile tools that can be used for straight and curved cuts.

When cutting curves with a jigsaw, it’s important to use a blade with fine teeth so that the cuts are clean and precise.

Another option is to use a router. Routers are typically used for shaping edges and making decorative cuts, but they can also be used for cutting curves.

Like with a jigsaw, it’s important to use a router bit with fine teeth when cutting curves in wood.

No matter what method you choose, taking your time and being careful will help you get the best results possible.

Conclusion

Yes, a reciprocating saw can cut curves. You will need to use a blade that is designed for cutting curves, such as a metal cutting blade. The blade will need to be long enough to reach the entire curve.

I’m John Carry, also known as a woodworker I have been a professional saw expert for over 10 years. I’d work with every type of saw machine out there, and experiment to find which tools work better.

I’m always looking for ways to improve my skills and help those around me. I love my job and am always happy to share my knowledge with others.